Established in 2002, 2 plants in Shenzhen and Ganzhou respectively, total 2150 employees. Sun&Lynn is one of the leading PCB manufacturing in China, offering one-stop PCB solution from quick turn PCB prototype to volume PCB manufacturing. Markets we serve include telecommunication and networking , industrial, automotive, energy , security , healthcare etc.

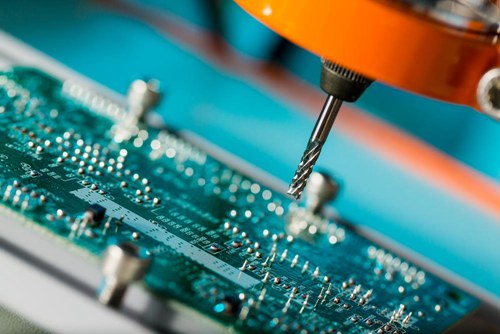

Main product in Shenzhen plant : conventional PCB, Copper base PCB, Aluminum Base PCB, Ceramic PCB, High-Frequency PCB, Multilayer PCB and etc.

Main product in Ganzhou plant: HDI, flexible, rigid-flex PCB and FPCA.

Sufficient Capacity

Production capacity in Shenzhen factory: 600,000sq.ft / Month .

Production Capacity in Ganzhou factory: total 800,000 sq.ft/ month , the structure as : Conventional PCB: 200,000 sq.ft / month , HDI: 400,000 sq.ft /month ; FPC:150,000 sq.ft / month and Rigid-Flex: 50,000 sq.ft.

Sun&Lynn remains 20% buffer capacity for new customers and new business.

?Business Review

2016 sale revenue was US$230M , keep 10% sales revenue increasing YOY since 2004 .

Global Sales Network

Sun&Lynn has established a global sales network and serves over 300 customers in 20 countries in world-wide. S&L is the strategic PCB supplier of GE, Philips, Commscope, Hitachi, Amphenol, Bourns, Omron, BYD, Honeywell, Hikvision, Emerson, ABB, RRC Solutions, Jabil, Sanmina-SCI, Plexus.

Leading Technology

400 engineers are with over 11 years of experience in PCB design and manufacturing, we have owned 79 patents of PCB technology. We spend 5% sales revenue on R&D every year for leading edge PCB technology and offer customized end-to-end solution from PCB design to manufacturing.

Robust Quality system

Certified in UL,ISO9000, ISO14000, OHSAS18001, EICC, TS16949, ISO13485, QC080000. etc.