What are they? What do they do?

Resident techies would be most familiar with the terms Printed circuit boards and rigid flex circuits; their usage would also be of no surprise or question. However, for those of us who may be just catching on to this already full-fledged tsunami wave, here’s a breakdown.

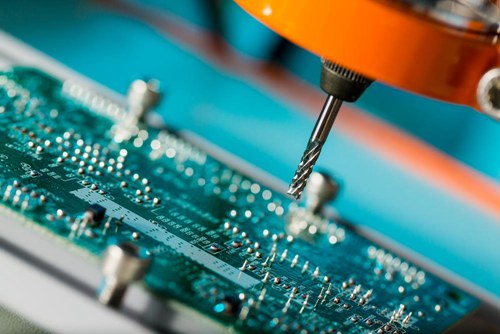

Printed Circuit Boards

Refers to a “thin board made of fibreglass, composite epoxy, or other laminate material”[1] They are commonly known to be used in PC’S but have also made their presence felt in mobiles and TV’s. Ideally, the PCB is said to support mechanically and electronically connects electronic components with the use of conductive tracks, pads, along with other features etched from copper sheets that are in effect laminated onto a non-conductive substrate.

Rigid flex circuits

It is in effect, a name given to a printed circuit that is a combination of both flexible circuits and rigid circuits.

Both come together to form a piece of equipment most undeniable in many industries. They are assembled with the usage of the soldering technique. The rigid PCB offers a sense of structure whilst the rigid flex PCB offers similar qualities just with the incorporation of multilayering. Key note, it has been said that military and the aerospace industries have both employed the usage of rigid flex PCB technologies for more than 20years. The combination of both rigid circuit boards and flexible circuit boards allow for optimization in the technological fields as the ability to manipulate its core make-up allows for usage across a variety of fields and equipment.

“Rigid flex printed circuit boards are boards using a combination of flexible and rigid board technologies in an application.”[2]Where it is that rigid circuit boards are present there is a multilayering system as it is designed to allow for flexibility whilst maintaining the overall structure. Rigid flex circuit designs are in fact more technical and detailed than the average printed circuit board as they are designed to function in a 3D space. Having to design and assemble a pliable piece of equipment that still functions up to scratch is a challenging task.

The rigid flex PCB’s have offered themselves to a wide variety of much needed equipment, be they in the fields of military, aerospace and more recently medicine in the case of pacemakers. Printed circuit boards are rigid and still have their place in the field of technology, but as the world leans more towards the diversification of equipment functionality it can be said that the rigid flex PCB is here to stay and further the development of cutting edge, ground breaking technology.

没有评论:

发表评论